“Bag in Box” - IBC System

The bag in box system is a unique and successful method to save you time and money on productivity, storage, distribution, hygiene, ergonomics, and packaging waste disposal.

Tote Solutions specialize in flat pack bag in box, intermediate bulk containers and are the leading supplier in North America to offer a complete system for any filling station from setup and filling thru to shipping and dispensing. We carry an extensive range of ancillary equipment to ensure the most versatile and efficient liquid handling bag in box container system available.

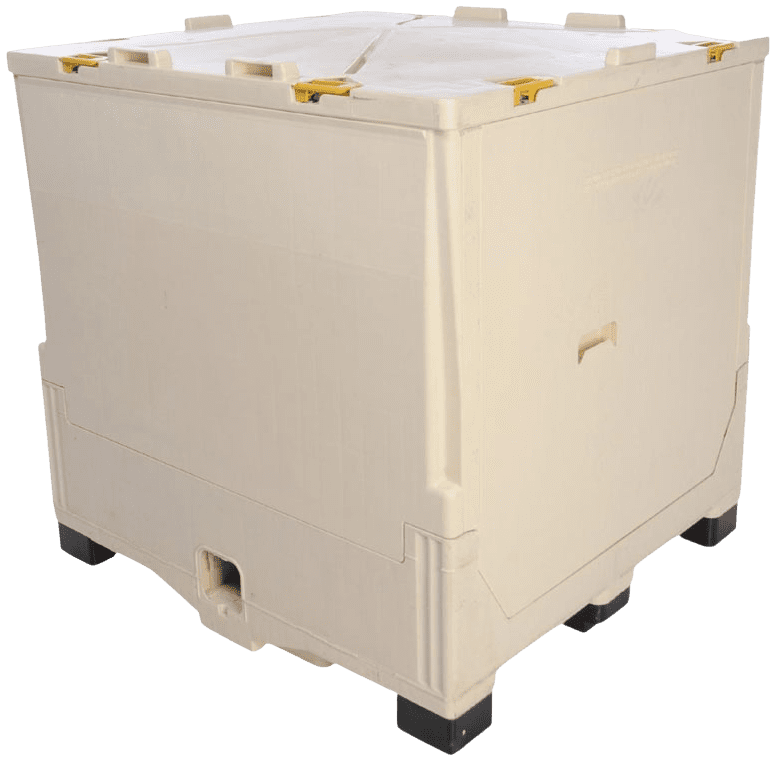

LiquiFold 315

is a multi-use, ergonomic, user-friendly injection molded food grade, recyclable, polypropylene IBC designed for a wide variety of liquid food products and non-hazardous industrial applications.

Liners

are available in a wide array of film structures and designs to fit your product-specific packaging requirements.

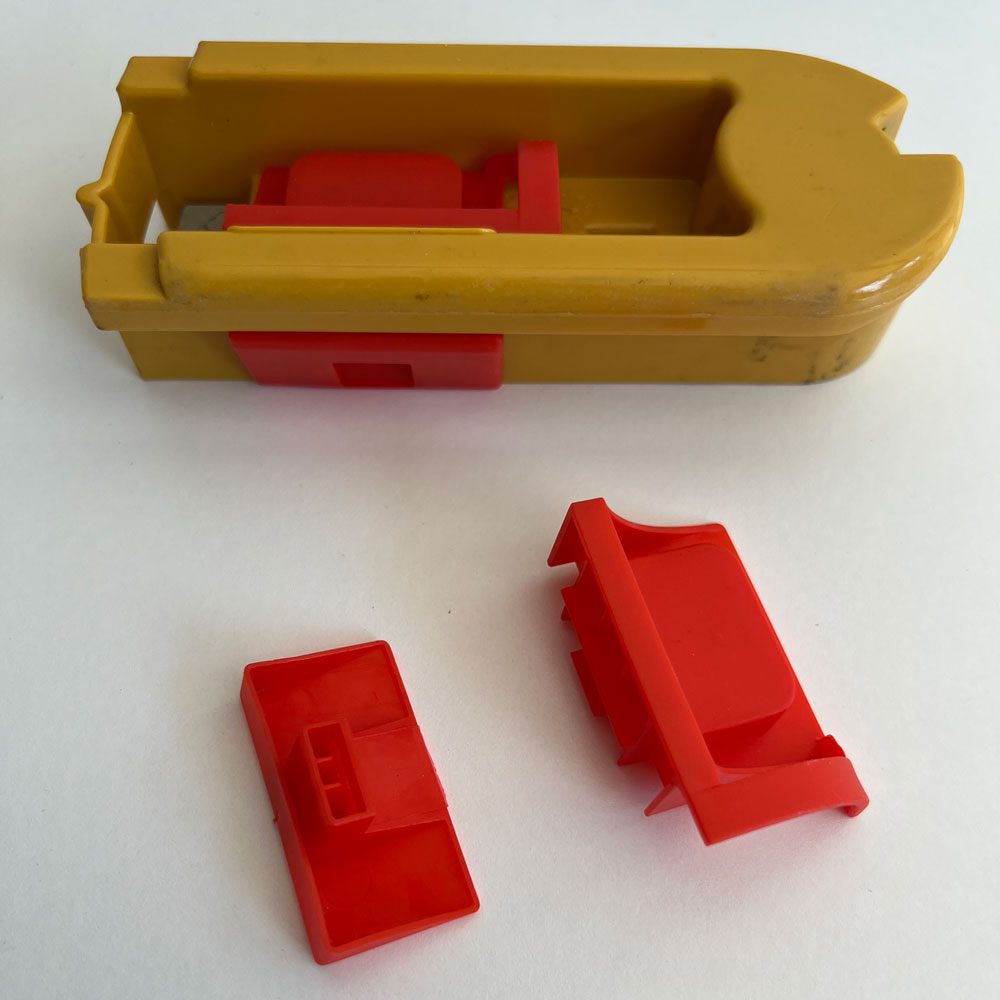

FlexiValve with Pusher Cutter Assembly

is a 2” butterfly valve and pusher cutter to push the crown cutter through the membrane of the liner and allow for efficient decanting. Constructed with food contact approved materials.

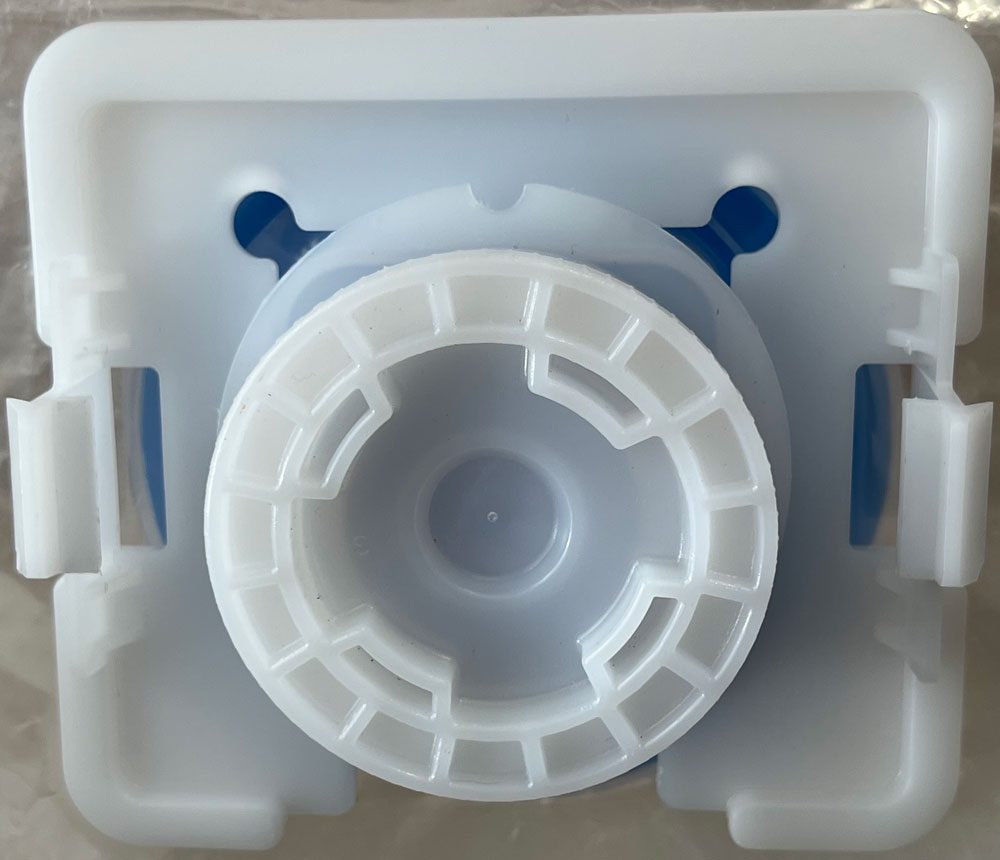

Gland Adapter

attached to liner to secure the dispense fitment valve to the container.

Grasping Tool

to facilitate the installation of the liner by attaching to the gland adapter when placing liner in IBC and pulling thru discharge opening to secure gland adapter to container.

Filling Bridge

to attach the filling gland on the liner bag for easy filling.

Tamper Evident Lid Handle Seals

are used to secure the LiquiFold 315 lid handles in place for HACCP compliance during storage and transportation.

Tamper Evident Discharge Cap Seal

available for the bottom discharge opening of the LiquiFold 315 for HACCP compliance during storage and transportation.

Adapters / Connectors / Valves

available in a wide range of options to ensure product handling ease, efficiency and safety for a variety of applications.

Sight Strip

is a fluid level indicator to show internal product levels for containers with solid walls and providing a continuous L.E.D. readout for quick reference.

Heater Mat

is an effective and very efficient method of introducing heat for high viscosity products.

Decant Lance

to assist decant flow of high viscosity products.

Washing Station

powerful automatic washing unit to clean the LiquiFold 315.

Winder Assembly

to aid in dispensing all your product from the liner.

Mixers

with folding propeller for blending or agitating product.

Flow Meters

to control and record batching, volume, mixing and rate of flow for your product.

Valve Support Cable

attachment to hold valve in place.

Weigh Scales

accurately measure the weight of your product.